AS-interface 在起重机系统中的应用

AS-Interface -

在环保型再生能源、电站中自动化起重机的应用

in the fully automatic crane system of environmentally-friendly biomass heating and power stations

西门子公司的AS-interface 应用于A+S Schuster起重机系统

AS Interface from Siemens used to network the A+S Schuster crane system

西门子与位于Peiting(德国)的起重机系统公司A+S Schuster 和VA GmbH公司合作,为Saalfelden / Salzburg的木材加工厂Schöβwendter Holz 提供了完整的环保型再生能源电站系统。在该电站中,燃烧舱的填料环节配备了全自动化的起重机系统。

Working in cooperation with the crane system construction company A+S Schuster and VA GmbH in Peiting, Germany, the wood working company Schößwendter Holz has constructed an environmentally friendly biomass heating and power station at its site in Saalfelden / Salzburg. This station has a fully automatic crane system for charging the firing bunker. A large part of the automation runs over the AS Inter- face field bus system.

加热站的运转全面实现自动化

The heating station now runs fully automatically!

加热站的燃烧舱由A+S Schuster的起重机系统填充燃料,该系统配置了AS-interface总线。 经多年的工程应用,A+S Schuster的起重机系统已经将AS-interface 作为其物流系统的标准方案。目前,在欧洲已经有4,000余套这样的系统(标准起重机系统和特制系统)在运行。根据与VA GmbH(VA=工艺加工厂)达成的协议,在许多同等类型的起重机系统中,对于分布的I/O的将广泛采用执行器-传感器接口系统(AS-interface).

The firing bunker of the heating station is charged by the A.S Schuster crane system, which is equipped with AS Interface. For some years now, A.S Schuster of Peiting, Germany has specialized in special solutions for transport tasks. There are now more than 4,000 of its systems (series crane systems and special constructions) in operation across Europe. In agreement with VA GmbH (VA = process engineering plants) it was decided to interface the distributed I/O of this and many comparable crane systems using the actuator-sensor interface field bus system (AS Interface).

为什么使用AS-interface?

Why AS Interface?

之所以在改系统中使用AS-interface技术的决定性因素是:它能够最大限度地减少起重机系统中大量的托链电缆数量。下面的对照,我们会清楚地了解这一优点:通常一个典型的案例我们需要在托链线缆槽中需要布置大致120根线缆,然而,使用新技术我们只需要总共10根电缆-5根AS-interface电缆和5根动力电缆。勿庸置疑,单从安装的角度来讲已经很具有说服力。

The decisive advantage of the AS Interface technology was the drastic reduction of wires that needed to be laid along the trailing cable that was previously an integral part of crane applications. Using conventional wiring, approx. 120 lines used to be laid along the trailing cable, whereas this crane system requires a mere 10 wires - 5 for AS Interface, 5 for the load. It goes without saying that this makes installation considerably easier all round.

西门子AS-interface 的应用特点:

The application advantages of the AS Interface from Siemens:

系统的远程维护简便而有效。在Schöβwendter Holz的现场通过触摸屏就可以实现系统的诊断。在线连接了实现远距离通讯。

SchSimple and effective remote maintenance. The diagnostics of the system can be performed over touch panel from the Schößwendter Holz site. An online connection enables communication over greater distances.

总线技术的应用使得系统的维护更有效。任何故障和断线都能够快捷地得到诊断和定位。

Bus technology makes maintenance of the system more effective. Faults and cable breaks can be localized quickly and easily.

系统的扩展异乎寻常的简单。

Uncomplicated expansion of the system.

通过模拟量输入输出模, AS-interface 同样能够处理模拟量信号。基于此,这些自动化的起重机系统通过AS-interface所连接的压力变送器上的检测信号来判断负载状况。对“负载下限”值的数据检测,系统会判断起重钩是否触底。AS Interface also supports the processing of analog data over analog modules. These automatic crane systems also make use of the ability to determine the load through AS Interface using force transducers. Using the "minimum load" limit value, the system is able to detect that it has touched down.

位于Saalfelden (德国)的Schößwendter Holz 再生能源电站。

The biomass heating and power station from Schößwendter Holz in Saalfelden, Germany.

一台自动化的起重机为燃烧舱填充燃料

A fully automatic crane system charges the bunker.

起重钩的检测信号直接接入K60型的AS-interface模板。

The signals at the grab are detected directly over the K60 AS Interface compact module.

起重钩的检测信号直接接入K60型的AS-interface模板的详图示例。

The signals at the grab are detected directly over the K60 AS Interface compact module (detail).

提交

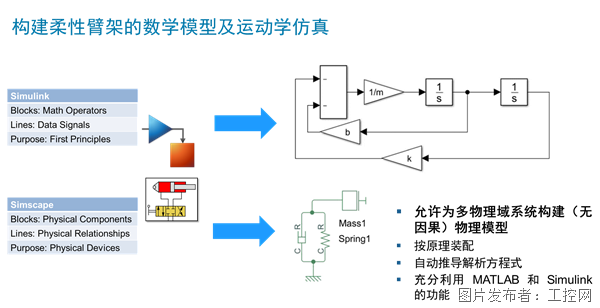

超越传统直觉,MATLAB/Simulink助力重型机械的智能化转型

新大陆自动识别精彩亮相2024华南国际工业博览会

派拓网络被Forrester评为XDR领域领导者

智能工控,存储强基 | 海康威视带来精彩主题演讲

展会|Lubeworks路博流体供料系统精彩亮相AMTS展会

投诉建议

投诉建议