- 型号:3029/4039/4045/6068/6081/6125

- 数量:100

- 制造商:宁波北仑日兴动力科技有限公司

- 有效期:2020/7/1 0:00:00

温馨提示

宁波日昕动力科技有限公司建立了一套完整的美国强鹿JOHN DEERE柴油机、柴油发电机零配件供应体系,全天候快速响应,纯正的美国强鹿JOHN DEERE柴油机、柴油发电机配件是您最佳的选择,因为您所得到的是延长美国强鹿JOHN DEERE柴油机、柴油发电机动力系统寿命的最佳保证。

特别声明:我司只销售强鹿JOHN DEERE柴油机、柴油发电机原厂配件,需付厂或防品件请绕道,谢谢。

强鹿JOHN DEERE柴油机配件有:活塞环喷油器滤清器修理包燃油泵油封节温器燃油管水管仪表电器螺栓螺母活塞冷却喷咀凸轮轴衬套皮带软管连杆瓦主轴瓦齿轮机油油嘴 PT泵配件 抱箍卡箍 调速板 电控板 气门 缸盖 活塞 缸套 连杆 曲轴 缸体 排气管 水箱 空压机 机油冷却器 机油盘 中冷器 热交换器 风扇 充电机 起动马达 齿轮室盖 辅助驱动 减振器 飞轮壳 飞轮 摇臂 凸轮从动件 增压器 机油泵 海水泵 水泵 润滑油 油咀 油泵 滤清系统 涡轮增压器 PT燃油泵 滤芯 支架 隔套 进气管 皮带轮 机油尺管 油管 防护罩 接头 密封圈 紧固件 垫片等配件

约翰迪尔美国强鹿JOHN DEERE全系列产品型号有:3029DF128、4039DF008、4045TF258、6068TF158、6068TF258、6068HF158、6068HF258、6081HF001A、6081HF001B、6125HF070A、6125HF070B、6125HF070C。

John Deere约翰迪尔强鹿柴油发动机气缸盖和阀门的修理和调整

Check Valve Lift Serial Number

( —199,999)

RG5789 –UN–09AUG91

Checking Valve Lift

IMPORTANT: For a more accurate measurement, it is

recommended that valve lift be

measured at 0.00 mm (in.) valve

clearance and with engine COLD.

NOTE: Measuring valve lift can give an indication of wear

on camshaft lobes and cam followers or bent

push rods.

1. Remove turbocharger oil inlet clamp and rocker arm

cover. Loosen lock nut on rocker arm. Set valve

clearance at 0.00 mm (in.) on valve being checked.

Tighten lock nut.

2. Put dial indicator tip on valve rotator. Be sure that

valve is fully closed.

3. Check pre-set on dial indicator. Set dial indicator

pointer at zero.

4. Manually turn engine in running direction, using the

engine rotation tools previously mentioned for checking

valve clearance.

5. Observe dial indicator reading as valve is moved to

fully open position. Record reading and valve number.

Specification

Intake Valve—Lift 13.53—13.71 mm

(0.533—0.540 in.)

at 0.00 mm (in.)

..........................................................

Wear Tolerance 12.65 mm (0.498 in.)

at 0.00 mm (in.) clearance

........................................................

Exhaust Valve—Lift 14.52—14.70 mm

(0.572—0.579 in.)

at 0.00 mm (in.)

.......................................................

Wear Tolerance 13.64 mm (0.537 in.)

at 0.00 mm (in.) clearance

........................................................

6. Repeat procedure on all remaining valves.

7. Reset valve clearance to specification after measuring

lift. See CHECK AND ADJUST VALVE CLEARANCE

SERIAL NUMBER ( —199,999) earlier in this group.

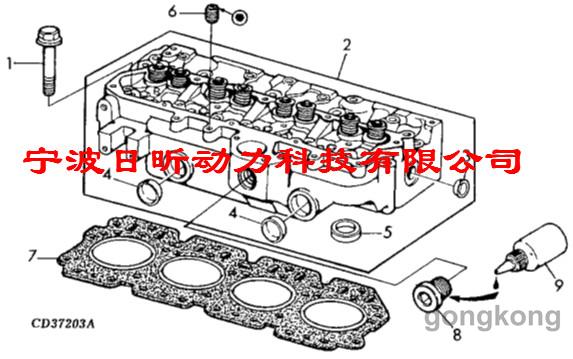

John Deere约翰迪尔强鹿柴油发动机拆下气缸盖

Remove Cylinder Head Serial Number

( —199,999)

A—Coolant Manifold

B—Turbocharger

C—Intake Manifold

D—Exhaust Manifold Assembly

It is not necessary to remove engine from machine to

service cylinder head on all applications. Refer to your

Machine Technical Manual for engine removal procedure,

if required.

CAUTION: After operating engine, allow exhaust

system to cool before working on engine.

DO NOT drain coolant until the coolant

temperature is below operating temperature.

Always loosen drain valve slowly to relieve any

excess pressure.

1. Drain engine oil and coolant. Disconnect turbocharger

oil inlet line at turbocharger or oil filter base. See

DISCONNECT TURBOCHARGER OIL INLET LINE in

Group 010.

NOTE: If cylinder head is being removed for piston and

liner repairs or any other service that does not

require disassembly of head, cylinder head can be

removed with coolant manifold (A), turbocharger

(B), intake manifold (C), and exhaust manifold (D)

installed.

2. Remove coolant manifold and all coolant piping. See

REMOVE COOLANT MANIFOLD in Group 070.

3. Remove turbocharger. See REMOVE

TURBOCHARGER in Group 080. Remove front and

rear exhaust manifold (D). See REMOVE, INSPECT

AND INSTALL EXHAUST MANIFOLD in Group 080.

4. Remove air intake manifold. See REMOVE, INSPECT

AND INSTALL INTAKE MANIFOLD in Group 080.

5. Remove fuel injection delivery lines and injection

nozzles. If mechanical fuel system, see REMOVE

FUEL INJECTION NOZZLES in Group 090 of

CTM243. If Level 3 Electronic fuel system, see

REMOVE FUEL INJECTION NOZZLES in Group 090

of CTM134.

6. Remove rocker arm cover with ventilator outlet hose

assembly.

7. Loosen all rocker arm adjusting screws before

removing assembly.

8. Remove six cap screws and remove all four rocker arm

shaft clamps (A). Lift rocker arm assembly (B) up and

remove. Remove wear caps from valve stems.

9. Remove all 12 push rods and identify for reassembly.

NOTE: Clean and inspect push rods. See CLEAN AND

INSPECT PUSH RODS SERIAL NUMBER ( —

199,999) later in this group.

A—Rocker Arm Shaft Clamps

B—Rocker Arm Assembly

10. Remove all 26 cylinder head cap screws. Discard cap

screws, they are not reusable.

IMPORTANT: DO NOT use screwdrivers or pry bars

between cylinder block and cylinder

head to loosen head-to-block gasket

seal.

11. Lift cylinder head from block. If cylinder head sticks,

use a soft hammer to tap the cylinder head.

12. Remove cylinder head gasket. Inspect for possible oil,

coolant, or combustion chamber leaks. Also, check for

evidence of incorrect or defective head gasket being

used.

NOTE: Do not rotate crankshaft with cylinder head

removed unless all cylinder liners are secured

with cap screws and large flat washers as

described in Group 030. See REMOVE PISTONS

AND CONNECTING ROD ASSEMBLIES in Group

030.

- 电话:15088860848 0574-26886646

- 传真:0574-26892499

- email:ygx556@163.com

手机扫描二维码分享本页

工控网APP下载安装

工控速派APP下载安装

| 评价: | 一般 | ||

约翰迪尔强鹿柴油发动机气缸盖和阀门的修理和调整

约翰迪尔强鹿柴油发动机气缸盖和阀门的修理和调整